Overview

With the increase in demand for services Hollyhock tech helps companies to access potential manufacturers, enabling them to take advantage of high quality standards and cost effective manufacturing parts from India.

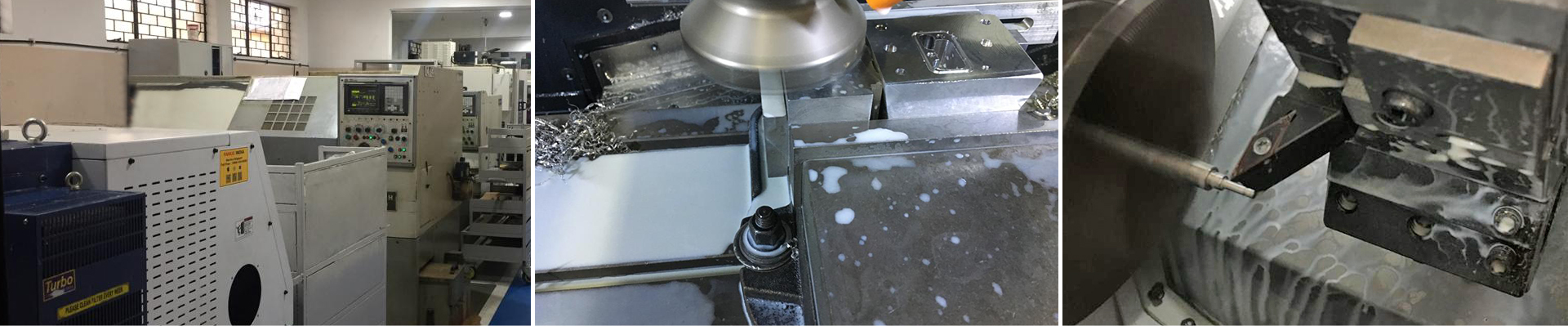

The Indian manufacturing sector has become a major destination for global players in the field of CNC machining.

Small and medium enterprises have upgraded from conventional machines to more faster and high precision CNC machines. Though the technology has penetrated deep but the exposure to the world is still limited.

Hollyhock tech has been helping its clients for the past 15 years to benefit from sourcing good quality parts at reasonable cost in the domestic market.

Hollyhock tech can link time-trusted, reliable and quality suppliers with clients so that the clients can take advantage of globalization and offshore outsourcing and reduce their input costs.

Your business can now explore these low cost markets with our trusted suppliers who understands the importance of quality and on time delivery in a number of specialized areas.

For a successful project, we don’t just provide quotations and place orders. Our engineers will keep in close contact with suppliers at each stage to ensure constraint free production of quality parts.

We review and ensure pre dispatched inspection happens before packing & shipment. We understand how important it is to have face to face contact with suppliers and customers, and that is part of our job as well.

Vision

To connect the Indian manufacturing Ecosystem with international OE manufacturers for improved efficiency & increased profits.

Mission

Our aim is to make a system to continuously fine tune the cost to realize profits through cultural changes and by bringing in strong systems.

To establish an effective system, the people should follow the system and system should run the show.

Founder’s Profile & Tenets

Vikas Arora ( Founder & Director)

- With over 18 years of experience in manufacturing industry serving variety of machining verticles.

- Mentored & trained employees on procedures regarding systems & troubleshooting.

- Served as a consultant & technical assistance to various organisations through evaluation, team building & engagements.

- Cultivated a supplier base for the clients of which many have turned into strategic partners.

Education :

A graduate in Production Engineering with a MBA in International Business and Operations Management

Experience :

| 2001-2003: | Marketing Capital Equipment |

| 2003-2010: | Owned & Managed a Machine Shop |

| 2010-2018: | Value Engineering & Sourcing |